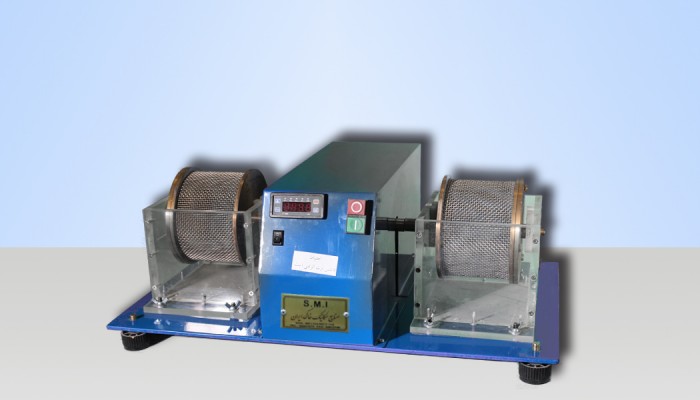

Slake Durability Apparatus

One of the most important problems with constructing structures on clay rocks is their ability to become weathered. Weathering causes a rapid change in the components of the rock and converts them into materials with very different properties from their original properties. The sensitivity of a rock to weathering and the occurrence of weathering is measured by a parameter called the index of durability - fragmentation and expressed quantitatively. Durability Index - Split is one of the most important geotechnical features of gypsum, marl, weakly cemented conglomerate and siltstone. This parameter is also used in the modified geo-mechanical classification.

In order to determine the durability index of stone splitting, Iran Soil Mechanics industry take action to build required test devices according to ASTM, It has two mesh containers with a diameter of 140 mm and a length of 100mm and with 2 mm grid size of mesh. These two compartments are located in separate reservoirs for submergence in water which is rotated by an electric drive at a speed of 20 rpm. The material of mesh compartments is made of brass metal and the water tanks from Plexiglass.

|

Standard:

|

ASTM D4644

|

|

Slake Durability Apparatus

|

SMRO-2410

|

Technical Specification:

|

Dimensions:

|

65×42×26 cm (L×W×H)

|

|

Weight Approx:

|

33 Kg

|

|

Container Dimensions:

|

Ø140×100 mm

|

|

Internal dimensions of the reservoirs:

|

14.5×17.5×14.5 Cm (L×W×D)

|

|

Mesh:

|

2 mm

|

|

Speed:

|

20 rpm

|

|

Timer:

|

Digital

|

|

Power Supply:

|

220 V, 50 Hz, 1 Ph

|