Hand Compaction

One of the types of asphalt is called asphaltic concrete, which is made using continuous fractured aggregates and pure bitumen with a degree of penetration of between 60 and 100. There are several methods for producing asphalt concrete and asphalt planes, among which the following three most commonly used methods can be enumerated.

- Marshall Method

- Haberfield Method

- Hveem (Gyratory) Method

All three of these methods have actually had satisfactory results, but what is most well-known in Iran is Marshall Method. Haber Field's method is most commonly used in asphalt concrete designs with a fairly fine aggregate, such as asphalt, in which materials of 100% of grade 4 grades are rejected. In the Hveem (Gyratory) Method, the asphalt samples are rubbed with rubbing, and the size of the largest asphalt beads is one inch as the Marshall Method. Marshall's method was first introduced by engineer Bruce Marshall, and later there were a lot of changes made until it became the current one. This method is described in detail in ASTM D1559.

The samples prepared by Marshall in order to find the relationship between density and the percentage of bitumen, to gain the relationship between specific gravity and bitumen percentage and the relationship between the percentage of bitumen and empty space, compressive strength and drawing the related charts, and also used for indirectly cutting of asphalt.

|

Standards:

|

ASTM D1559, BS 598-107, EN 12697-30

|

Equipment needed to make a 4” sample:

|

Ordering |

Description |

Technical specification | |

|---|---|---|---|

|

SMAS-3110

|

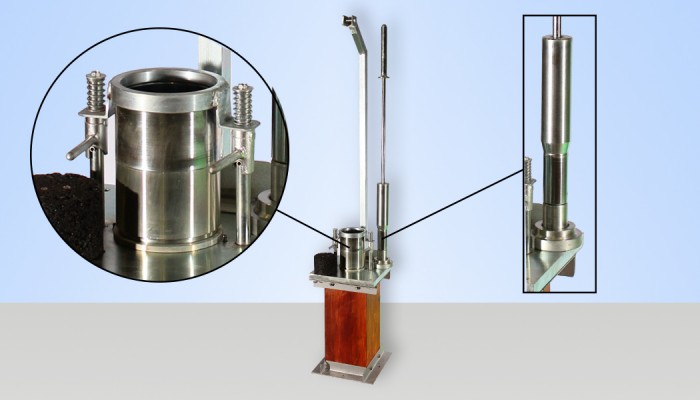

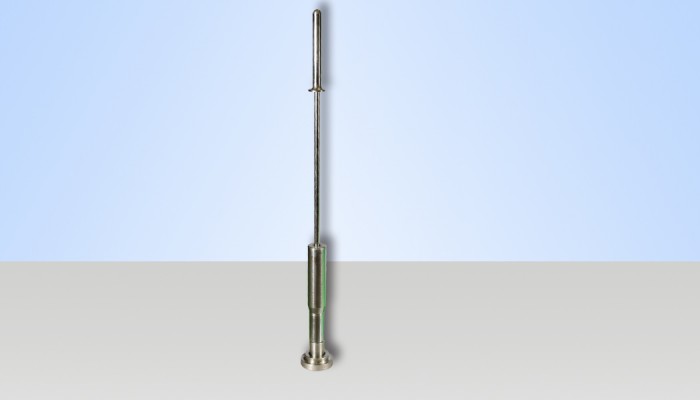

Compaction Hammer

|

Dimension

|

Ø100×1075 mm

|

|

Total weight of hammer

|

8.700Kg

|

||

|

Height of fall

|

457 mm

|

||

|

Weight of weights

|

4.5 Kg

|

||

|

SMAS-3101

|

Compaction Pedestal

|

Included:

|

|

|

Dimension

|

29×32×112.5 Cm

|

||

| Weight | 18.400 Kg | ||

|

SMAS-3120

|

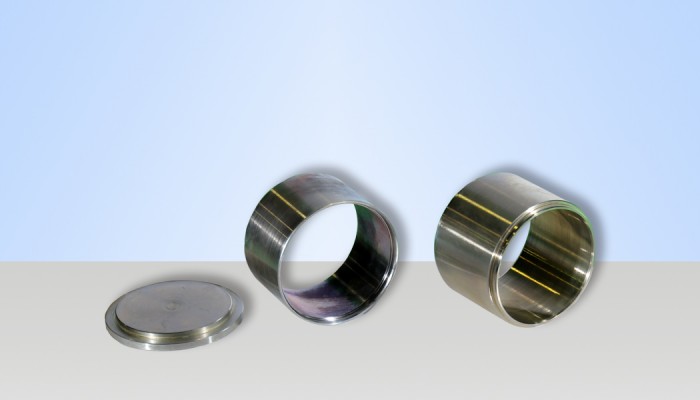

Compaction Mould

|

Included:

|

|

|

Dimension

|

According to the standard

|

||

| Weight |

3.200Kg

|

||

|

SMAS-3199

|

Laminated hardwood block

|

Dimension without the up and down frame |

19.5×19.5×45 Cm

|

| Total Dimension |

30×30×45 Cm

|

||

| Weight |

15.5 Kg

|

||

|

Made of the hardwood pieces and glued and pressed together

|

|||

Equipment needed to make a 6” sample:

|

Ordering |

Description |

Technical specification | |

|---|---|---|---|

|

SMAS-3160

|

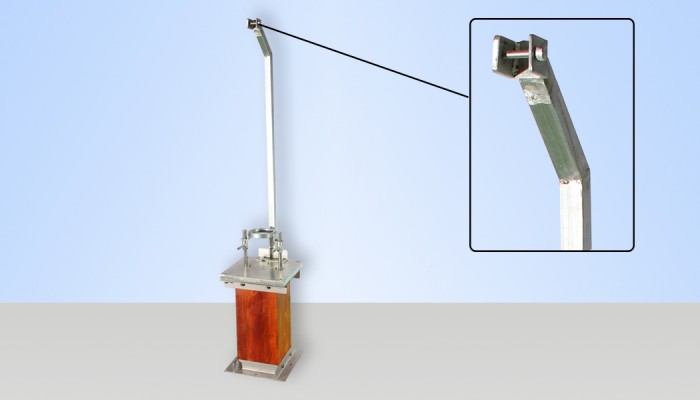

Compaction Hammer

|

Dimension |

Ø150×1075mm

|

|

Total weight of hammer

|

15.5Kg

|

||

|

Height of fall

|

According to the standard

|

||

|

Weight of weights

|

According to the standard

|

||

|

SMAS-3151

|

Compaction Pedestal

|

Included:

|

|

|

Dimension

|

29×32×112.5 Cm

|

||

| Weight | 18.400Kg | ||

|

SMAS-3170

|

Compaction Mould

|

Included:

|

|

|

Dimension

|

According to the standard

|

||

| Weight |

6.200 Kg

|

||

|

SMAS-3199

|

Laminated hardwood block | Dimension without the up and down frame |

19.5×19.5×45 Cm

|

| Total Dimension |

30×30×45 Cm

|

||

| Weight |

15.5 Kg

|

||

|

Made of the hardwood pieces and glued and pressed together

|

|||