Marshall Stability and Flow

The compressive strength or compression strength of the Marshall is the maximum tolerance of the Marshall Test sample without fracture. This strength alone is not a sustainability criterion, but two criteria for Marshall and Psychic compressive strength parameters should be considered together to determine this criterion. Deformation of asphalt relative to the creep deformation of asphalt or mental or in other hand called asphalt deformation under load. Whatever more ratio (proportion) deformation, the amount of the creep will increase by affected load.

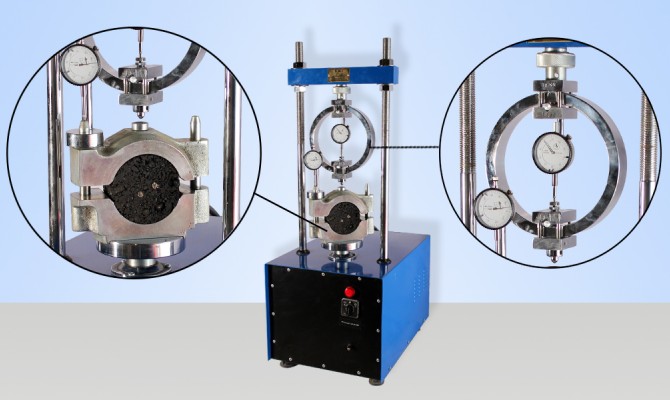

Marshal device manufactured by Soil Mechanics Industries of Iran used for marshal testing and determine the compressive strength and percentage deformation ratio of an asphaltic concrete which in standard conditions, and compacted in a special mould. After preparation of the samples and keep at a standard temperature, set it in a particular jaw and loaded by marshal device with speed of 50.8 mm per minute. Specimen deformation measured by special gauge, the test performed According to the valid standards such as ASTM D6927, this test used in the different type of asphalt.

|

Standards:

|

ASTM D6927, BS 598-107, EN 12697-34,

|

Technical specification:

| Description | 3 Ton Analogue Marshall Test |

3 Ton Digital Marshall Test |

5 Ton Analogue Marshall Test |

5 Ton Digital Marshall Test |

|---|---|---|---|---|

|

Ordering Code |

SMAS-4100 |

SMAS-4101 |

SMAS-4200 |

SMAS-4201 |

|

Dimension L×W×H |

55×38×102 Cm |

55×38×102 Cm |

...×...×... Cm |

...×...×... Cm |

|

Weight Approx. |

86 Kg |

86 Kg |

... Kg |

... Kg |

|

Device capacity |

30 KN |

30 KN |

50 KN |

50 KN |

|

Load Ring/Load Cell |

30 KN |

30 KN |

50 KN |

50 KN |

|

Loading speed |

2 in/min |

2 in/min |

2 in/min |

2 in/min |

|

Sample Size |

4 Inch |

4 Inch |

6 Inch |

6 Inch |

|

Displacement Course1 |

22 mm |

22 mm |

... mm |

... mm |

|

Maximum internal openings |

225 mm |

225 mm |

... mm |

... mm |

|

Maximum internal height2 |

185 mm |

185 mm |

... mm |

... mm |

|

Power Supply |

220 V, 375 W, 1 ph |

220 V, ... W, 1 ph |

||

-

The device has a micro-switch to prevent the movement limit from being exceeded.

-

From the loading plate up to below of the load cell ring.

Machine included parts:

-

Load Ring / Load Cell according to the model and capacity.

-

Vertical Dial Gauge / Vertical Sensor with accuracy of 0.01 and travel of 25 mm.

-

Flow meter pedestal.

-

Marshal jaw (Stability jaw) proportional to the model of device.

-

The spherical end of load cell ring / Force sensor for positioning on the jaw.