Setting Time Vicat Method

Due to the concentration of the mixture (the ratio between the amount of water and cement) the speed setting of cement, in other words, affected at the speed of dough fluidity, the initial setting time should be determined by the amount of the specified water (normal concentration), until the test results for different samples can be compared with the other Portland Cement, or could be test for a particular cement sample compared to the amount which listed in specifications of factory. In relation to the importance of this test, considering that before the primary initial setting time of cement, the amount of cement setting is immaterial, so all operations, manufacturing, transport, pouring, compaction and concrete polishing must be done in this time frame, otherwise any concrete movement when the concrete is hardening, cause to reduce reliability and compressive strength. This subject is important in situations where distance between the site of production and the use of concrete is far from site or if concreting operations are faced with some problems, in any case before the initial setting time of concrete must be in their final positions. Use of this test is to identify the setting time of Portland Cement, For example, initial setting time of slow setting cement is more than ordinary or fast-setting cement are in the same condition obviously should be done for the prototype test determine the normal concentration. Also this test is used to evaluate the quality of cement which is used in workshop, because of corrupt cement setting time are more than usual limit. The final setting time is the time elapsed from the moment of mixing water and cement until the efficiency of the dough is completely eliminated. Thus final setting time could be considered as the start of the final hydration operation of and end of the cement setting operation. The final setting time is not very widely (Extensive) usage but can be used to determine the extent time for the finishing operation and trowel work of exterior view of the concrete

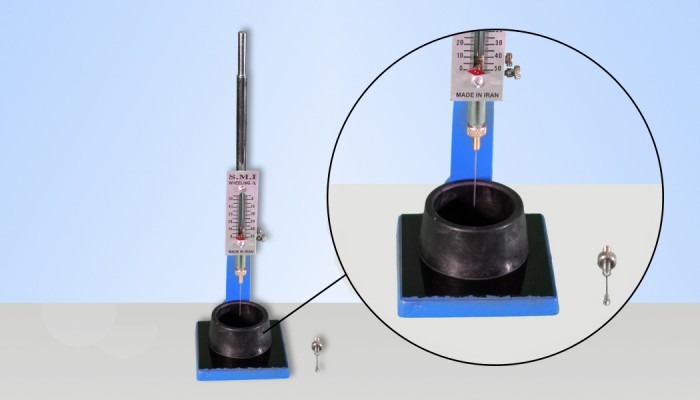

In order to determine the initial and final setting time of cement as well as the preparation of cement paste with normal concentration, it's required to Vicat Device. The vicat devices which made by our company includes: a rigid chassis, scaled ruler, measuring indicator of the penetration, the main piston, needle penetration and sample mold.

|

Standards:

|

ASTM C187, C191, EN 196-3, 13454-2

|

Specifications:

| Ordering Code | Description |

Weight |

Technical Specifications |

|---|---|---|---|

|

SMCE-3110 |

Vicat Apparatus |

1895 |

Included: Initial Set Needle, Final Set Needle, Main Piston, Mould |

|

SMCE-3111 |

Initial Set Needle |

15 |

Diameter of the needle 1mm, length of the needle 47mm, |

|

SMCE-3112 |

Final Set Needle |

15 |

Diameter of needle tip 5mm, Diameter of needle body 14mm, the length of the needle 31mm,

complete length 62mm, stainless steel with brass end / screwed both side |

|

SMCE-3113 |

Vicat Main Piston | 300 |

With one end diameter of 10mm and length of 50mm |

|

SMCE-3114 |

Vicat Mould |

80 |

Material: Teflon PTFE

(Poly Tetra Fluor Ethylene)

ID 60/70 mm top/end, 40 mm High

|