Moulding of Prisms

For compressive strength and bending tests of cement need to build a sample with the specific dimensions. For this purpose, after the preparation of cement paste or mortar with the aid of a mixer, the resulting mixture is poured into cube or prism molds, cover the surface of mold with glass or a plastic perfectly smooth and keep for 24-hour in mold.

In order to avoid adhesion of cement to the wall of mold Cubic or Prismatic sampling mould has three-gang, when mould components are connected mold, must be reliably secured. Molds are made from hard metal that does not stick to the cement, the walls of the mold are coated with a thin layer of mineral oil, cubic samples compacted by cement mortar hammer in three layers, for setting the samples must leave the samples one day in the mould, and then removed from the mold and until the testing time submerged in water.

|

Standards:

|

ASTM C109, BS 1881-131, 3892-1, 4551-1, EN 196-1, 413-2, 459-2, 1744-1, 1015-10, 13454-2

|

Specifications:

| Ordering Code | Description |

Outside mm |

Weight kg | Material |

|---|---|---|---|---|

|

SMCE-7205 |

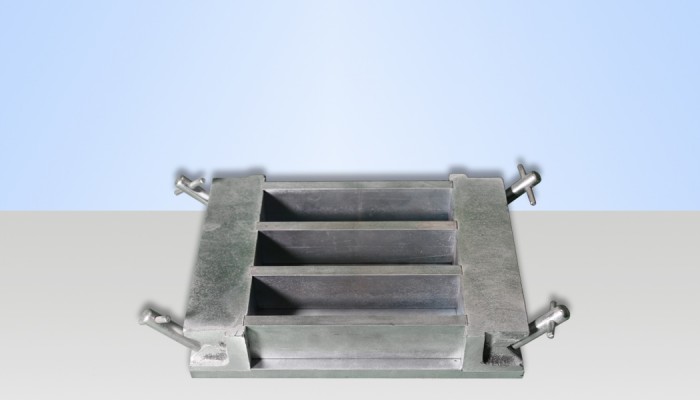

Three-gang mould mortar of cement 50×50×50 mm |

265×140×60 |

5.2 |

Brass casting |

|

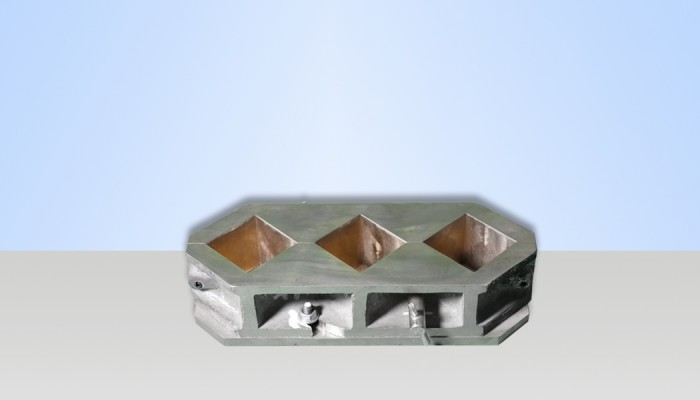

SMCE-7210 |

Three-gang mould mortar of cement 40×40×160 mm |

320×190×70 |

9.3 |

Stainless steel |

|

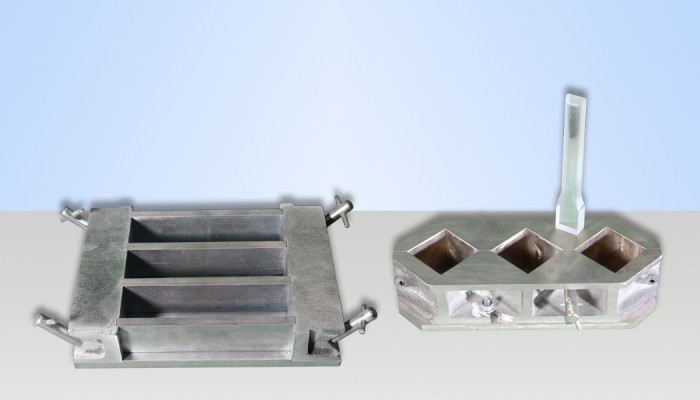

SMCE-7201 |

Mortar of cement Hammer |

25×15×150 |

45 |

Plexiglas |

The possibility of build the moulds with different sizes and shapes are also available. Provide the maps and technical data is required at the time of order.