Micro-Deval

In recent years, the Micro-Deval test has been accepted and popularized as a cost-effective and accurate test for measuring aggregates abrasion. The basis of this method was invented in France in 1960 and with the help of it, the measurements of toughness (hardness), abrasion resistance and durability of aggregates in the vicinity of steel shots and water are obtained.

Materials that lose a small percentage of their weight in the test there will be more long life in the different stages of the project from the time of preparation and implementation up to exploitation and operation. There are separate methods for coarse and fine aggregates. To get the amount of abrasion after the test, they pass them through the sieve No. 16 or 200 and then weigh the rest.

| Standards: |

ASTM D6928, AASHTO T328

|

Mechanism and technical specifications of the device:

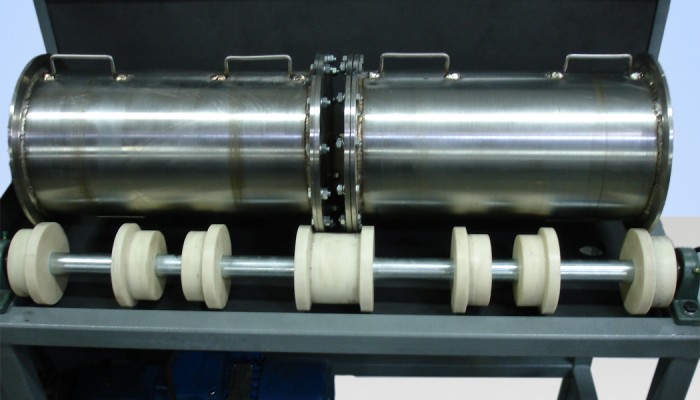

Separate some of the aggregates in the specific size, first weigh them (the amount is suitable for fine aggregates 500 grams and a large 1500 grams) and then pour them into the stainless steel tank. Add some water (about 2 liters) and leave it to stay in this state for an hour. After that, add abrasive stainless steel carbide (magnetically absorbent) balls and tighten the tank door. Put the tanks in place and set the device to a specific time and turn it on. Remove the sample from the tank then weigh after pass the sieve and washing and separating the shots with the help of magnets.

|

Ordering Code:

|

With Two Tanks |

SMAG-6420

|

|

|

With Four Tanks |

SMAG-6410

|

|

Overall Dimensions:

|

|

110×50×125 Cm (L×W×H)

|

|

Approximate Weight:

|

|

120 Kg

|

|

Power Supply:

|

|

220 V, 50 Hz, 1 ph

|

| Speed: |

|

100 rpm

|

|

Accessories:

|

1. 2 or 4 Stainless Steel Tanks

2. Tray to drain the sample after the abrasion

3. Magnetic Stainless Steel Balls

|

|