Capping of Cylinders

In testing the compressive strength in cylindrical shape of concrete, due to the need to apply uniform force on the contact area and prevent early fracture, both end of the sample put on (cover) by mortar fast harden cap. Mortar cap (Capping) of sulfur compounds and filler material (silica) is established. By mixing sulfur and silica due to standard with a certain ratio in the proper container and heating the mixture up to the melting point a mixture is obtained, which is used for capping of cylindrical concrete samples.

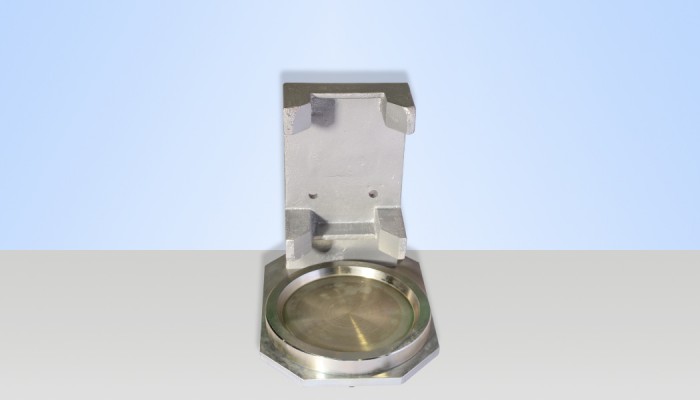

Pour the molten material into the lower part of a mold, which is called capping mold and then place the cylindrical sample from one side into the mold, so that's quite tangential to the wall of the mold and let it stiffen the molten mixture, then repeat this for the other side.

| Standard: | BS 12390-3 |

Melting Pot:

|

Ordering Code:

|

SMCO-1710

|

|

Volume:

|

3.4 Lit

|

|

Inside Dimension:

|

21×10 Cm ( D×H )

|

|

Outside dimension:

|

40×32×21 Cm ( L×W×H )

|

|

Temperature limit:

|

0 to 300 °C

|

|

Weight:

|

6 Kg

|

|

Cover Material:

|

Aluminum and Stainless Steel

|

|

Power Consumption:

|

220 V, 2000 W, 1 ph

|

|

Specifications of the device:

|

Digital temperature display

|

Cylinder Capping Frames:

|

Ordering

Code

|

Description

|

Dimension

Cm

|

Weight approx

Kg

| Material |

|---|---|---|---|---|

|

SMCO-1720 |

4" Diameter Cylinder Capping Frame | 21×15×17 | 4.3 | Iron & Aluminum |

|

SMCO-1730 |

6" Diameter Cylinder Capping Frame |

21×29×28 | 10 | Iron & Aluminum |