Concrete

One of the most common building materials is Concrete which has properties such as form a paste shape before hardening, setting, good resistance against fire, easy access to materials and good compressive strength, it had met with general acceptance to use it.

Concrete is a material like stones that obtained with mixing by proportional amounts of cement, sand, gravel, water and other additives. The main mass of concrete, coarse and fine grain of the stone (sand) and chemical interactions between water and cement, like an extract covered around the aggregate, it’s cause the integration and adhesion of the aggregate to each other. This aggregate are the main skeleton of concrete and with stand the force exerted on concrete, in cement water of the mixture caused a chemical reaction, the hardening of concrete mixture after a period of time about (twenty-eight days) it will reach the ultimate strength of concrete. In concrete mixture is formed with 65 percent of sand and gravel, and remaining cement paste and a very small percentage of air.

In the second half of the nineteenth century to overcome the limitations tensile strength of concrete, attempting to use steel bars with a high tensile strength in parts of the tension was concrete, steel has excellent adhesion to concrete in this combination one of the most important factors is the use of steel in concrete. The obtained combination of "Reinforced Concrete" (RC) called, which often has good benefits of two different materials by itself, and this desirable feature, reinforced concrete used in a variety of structures like Buildings, Bridges, Dams, etc. is possible. But in structures such as Arched Bridges, Dome Coverage, Ply Type Covers and Cylindrical Tanks due to bending factor involved in another type of concrete structures called "Prestressed Concrete" is used. The steel in the form of wire rod or cable to be pulled close to the yield point after concrete placement and the concrete and thus create the necessary adhesion between the steel and concrete factor tension in the steel removed and all steel tensile force is applied to the concrete pressure the ability to structure the force caused by the bending load increases.

In the process of using concrete, there are two essential factors which are very effective in reaching concrete to the final strength, structural design engineers, according to the existing regulations for different structures and confirm by taking into consideration of the design parameters.

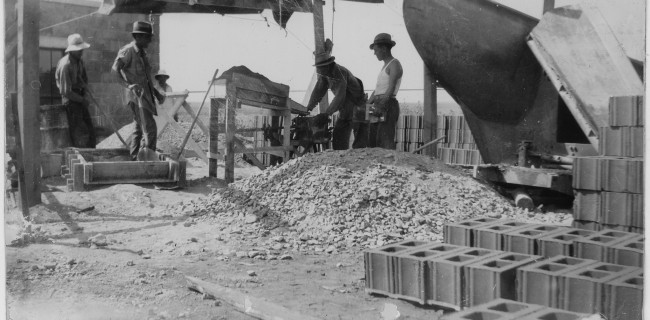

- Concrete Manufacturing

- Concreting

In the design process, the designer, using the existing regulations and taking into account the final strength required, declares the percentage of each of the concrete constituents, and the manufacturer will also build concrete with this instruction. In the second stage, the implementer of the project, in full compliance with the rules of concrete regulations, is to concreting and maintaining it until it reaches its ultimate strength. Failure to observe any of these rules will cause damage to the concrete during loading and in critical situations and cause irreparable damage. Therefore, the relevant bases should be fully monitored over the correct implementation of the rules by designers, concrete company and contractors, and regular inspections and tests of concrete resistance during all stages of construction and implementation of the damage caused by improper implementation of these regulations.