Small-scale Direct Shear

Direct shear tests is an important in the case of Geotechnical Engineering (Soil Mechanics and Foundation) to determine soil strength parameters in terms of consolidated-drained (CD). In this test, first soil under the specific vertical stress become consolidated, then while stabilizing vertical stress, shear stress is set to speed, apply to soil sample until the sample is ruptured. The maximum shear stress for a specific vertical stress, gives the coordinates of a point. Tests are usually performed with three different vertical stress and thus coordinate system "shear stress - vertical stress" three points is obtained that draw the best line passing through the points, soil strength parameters of (C, Φ) are determined.

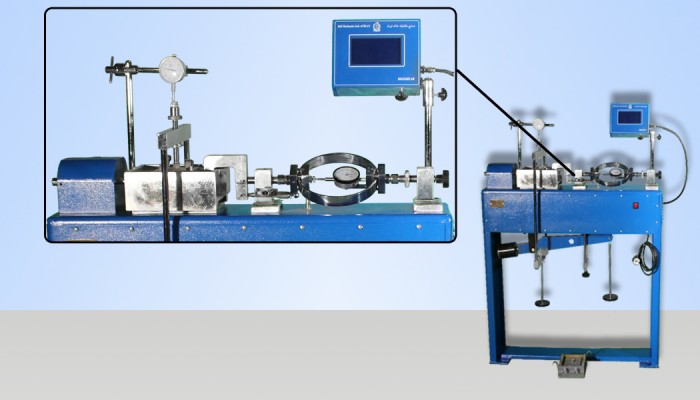

Direct shear test apparatus, which is manufactured by Soil Mechanic Industries of Iran Co., designed and produced accordance with international standards such as ASTM.

| Standards: | ASTM D3080, BS EN 1377, |

Technical Specifications:

|

Description |

Direct Shear Apparatus

60×60, 100×100 mm

Model DSH100

|

Direct Shear Apparatus

60×60, 100×100 mm

Model DSH101

|

|---|---|---|

|

Ordering Code |

SMSO-7100 |

SMSO-7101 |

|

Dimension (L×W×H)

|

90×31×135 Cm |

|

|

Weight approx |

110 Kg Without weights

|

|

|

Set of Weights |

39Kg = 2×10Kg + 2×5Kg + 2×3Kg + 3×1Kg |

|

|

Beam Ratio |

1:1 , 1:10 |

|

|

Sample Size |

60×60 mm , 100×100 mm |

|

|

Load ring / Loadcell Capacity1 |

200 Kgf |

500 Kgf |

|

Horizontal Dial Gauge /

Horizontal Sensor Capacity

|

0-20 mm, 0.01 |

0-25 mm, 0.01 |

|

Vertical Dial Gauge /

Vertical Sensor Capacity

|

0-10 mm, 0.01 |

0-10 mm, 0.01 |

|

Max. Horizontal Displacement |

20 mm |

|

|

Max. Horizontal Load |

1000 Kgf |

1000 Kgf |

|

Max. Vertical Stress |

10 Kgf/Cm2 |

10 Kgf/Cm2 |

| Uploading Speed Range |

0.001-9.999

mm/min

|

0.001-9.999

mm/min

|

|

Mini. Shear Speed |

0.001 mm/min |

0.001 mm/min |

|

Max. Shear Speed |

9.999 mm/min |

9.999 mm/min |

|

Power Supply |

220 V, 260 W |

220 V, 260 W |

|

Data Logger Unit2 |

Have Not |

Has It |

- Ability to change the capacity of load cell/force sensor according to buyer's requirements are available.

- Data Logger Unit:

- 16 bit.

- 4 input channels.

- Velocity of sampling: Up to 10 samples per second.

- Reading and Recording software included.

- Software of Analyzing results and Drawing necessary diagrams (Customized).

The other features of Direct Shear Apparatus:

Special Capability of custom models:

Sampling and Shearbox Accessories

|

Description |

Ordering Code |

Weight approx

gr

|

Outside Dimension

mm

|

Inside Dimension

mm

|

Material |

|---|---|---|---|---|---|

|

Ø50 mm Shearbox |

SMSO-7310 |

|

|

Ø50×20 |

Brass |

|

Grooved Shear Plate |

SMSO-7311 |

|

|

|

Brass |

|

Mesh Shear Plate |

SMSO-7312 |

|

|

|

Brass |

|

Mesh Grooved Plate |

SMSO-7313 |

|

|

|

Brass |

|

Sampling Rammer |

SMSO-7318 |

|

Ø50×130 |

|

Brass |

|

Specimen Cutter |

SMSO-7319 |

|

Ø55×20 |

|

Brass |

|

60×60 mm Shearbox |

SMSO-7320 |

3640 |

160×140×70 |

60×60×50 |

Brass |

|

Grooved Shear Plate |

SMSO-7321 |

330 |

60×60×11.5 |

Brass |

|

|

Mesh Shear Plate |

SMSO-7322 |

150 |

60×60×4.5 |

Brass |

|

|

Mesh Grooved Plate |

SMSO-7323 |

75 |

60×60×4.5 |

Brass |

|

|

Sampling Rammer |

SMSO-7328 |

625 |

60×60×130 |

Brass |

|

|

Specimen Cutter |

SMSO-7329 |

195 |

68×68×25 |

60×60×20 |

Brass |

|

100×100 mm Shearbox |

SMSO-7330 |

6670 |

160×146×71 |

100×100×30 |

Brass |

|

Grooved Shear Plate |

SMSO-7331 |

240 |

100×100×4.5 |

Brass |

|

|

Mesh Shear Plate |

SMSO-7332 |

485 |

100×100×6 |

Brass |

|

|

Mesh Grooved Plate |

SMSO-7333 |

230 |

100×100×4.5 |

Brass |

|

|

Sampling Rammer |

SMSO-7338 |

1340 |

100×100×130 |

Brass |

|

|

Specimen Cutter |

SMSO-7339 |

450 |

110×110×30 |

100×100×30 |

Brass |

|

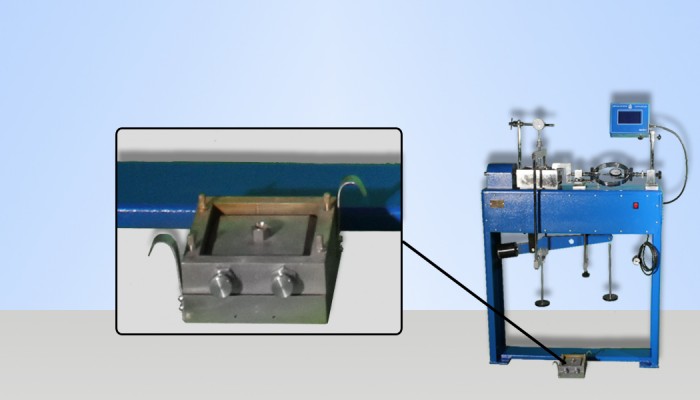

Saturated Boxes of

Direct Shear

|

SMSO-7390 |

7210 |

200×240×90 |

185×150×60 |

Brass |