Statics Triaxial Test

Triaxial tests is one of the most important experiments in Geotechnical Engineering (Soil Mechanics and Foundations) to determine soil strength parameters in different conditions (UU, CU, CD). In this experiment, based on the type of experiment, first the soil samples under mutual pressure (back pressure) and all-saturated, and after consolidation, while stabilizing the confining stress, vertical stress of soil samples with set speed will be inserted into the sample to be disrupted. The maximum vertical stress for a certain confining stress, axial stress, caused by the diameter of a circle in environment axial stress.

Tests are usually performed with three different confining stresses and thus in the coordinate system "stress shear, stress axis", three circles are obtained that which is draw the best line tangent to these three circles (Mohr's circle), soil strength parameters are determined.

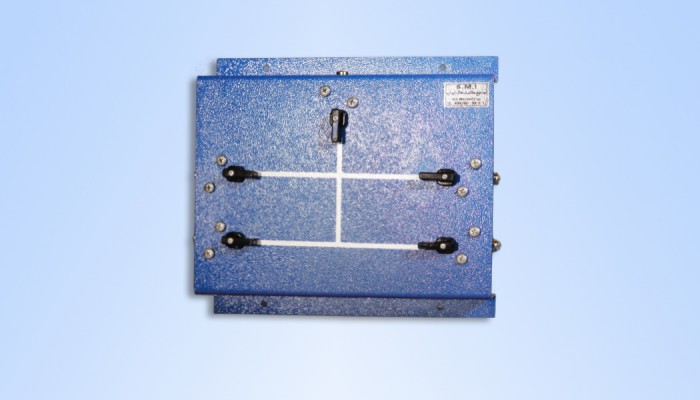

Triaxial testing machine manufacturing in S.M.I Co. in accordance with the international standards such as ASTM designed and built.

|

Standards: |

ASTM D2850, D4767, BS EN 1377-7, -8, AASHTO T296 T297 |

Technical Specifications:

|

Description |

5 Ton Triaxial

Test Machine

Model STR500 |

5 Ton Triaxial

Test Machine

Model STR501 |

10 Ton Triaxial

Test Machine

Model STR1000 |

10 Ton Triaxial

Test Machine

Model STR1001 |

|---|---|---|---|---|

|

Ordering Code |

SMSO-6200 |

SMSO-6201 |

SMSO-6250 |

SMSO-6251 |

|

Dimension (L×W×H) |

56×47×145 Cm |

56×47×145 Cm |

73×61×210 Cm |

73×61×210 Cm |

|

Weight approx |

107 Kg |

107 Kg |

300 Kg |

300 Kg |

|

Diameter of testing sample |

38 mm , 50 mm |

38 mm , 50 mm |

38 mm to 150 mm |

38 mm to 150 mm |

| Load ring / Loadcell Capacity1 |

500 Kgf |

1 Ton |

5000 Kgf |

5 Ton |

|

Vertical Dial Gauge /

Vertical Sensor Capacity

|

0-25 mm, 0.01 |

25 mm, 0.01 |

0-50 mm, 0.01 |

50 mm, 0.01 |

|

Max. Vertical Displacement |

50 mm |

50 mm |

70 mm |

70 mm |

|

Uploading Capacity |

5000 Kgf |

5000 Kgf |

10000 Kgf |

10000 Kgf |

|

Uploading Speed Range |

0.001 - 9.999 mm/min |

0.001 - 9.999 mm/min |

0.001 - 9.999 mm/min |

0.001 - 9.999 mm/min |

|

Power Supply |

220 V, 260 W |

220 V, 260 W |

220 V, 260 W |

220 V, 260 W |

|

Pump and Pressure

Indicating Panel

|

Customized

|

Have not | Customized | Have not |

| Pressure

Indicating Panel

|

Customized

|

Have not

|

Customized

|

Have not

|

|

Universal Pump and Pressure

Indicating Panel2 (NEW)

|

Has it |

Have not | Has it | Have not |

| Multilateral Pressure Sensor | Have not |

16 Bar |

Have not | 16 Bar |

| Mutual Pressure Sensor | Have not |

16 Bar | Have not | 16 Bar |

| Pore Pressure Sensor | Have not |

16 Bar | Have not | 16 Bar |

| Differential Mercury Manometer | Has it |

Have not | Has it | Have not |

| Twin-burette Volume Change3 | Has it | Have not | Has it | Have not |

| Volume Change Transducer | Have not | 80 cc, 0.01 cc sensitivity |

Have not | 80 cc, 0.01 cc sensitivity |

|

Bladder-type Air / Water

Pressure Assembly

|

2 No. | 2 No. | 2 No. | 2 No. |

| Data Logger Unit4 | Have not | Has it | Have not | Has it |

- Ability to change the capacity of load cell/force sensor according to buyer's requirements are available.

- Capacity of Universal Pump and Pressure Indicating Panel is 16 BAR with an accuracy of 0.05 BAR.

- Twin-burette Volume Change accuracy of 0.2 ml of sample volume with a maximum pressure is 1600 Kpa.

- Data Logger Unit:

- 16 bit.

- 6 input channels.

- Velocity of sampling: Up to 10 samples per second.

- Reading and recording software included.

- Software of Analyzing results and Drawing necessary diagrams (Customized).

The other features of triaxial test machine:

Special Capability of custom models: